|

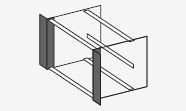

RXB components

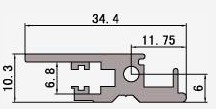

Front Flange |

|

|

Rack-mounted Flange

|

+Accessories : EMC (battery compatible) shielding shrapnel, vertical.

|

|

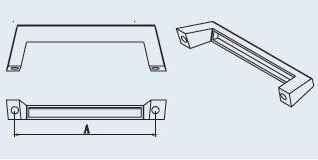

Handle More |

|

|||||||||

|

|

|||||||||||

|

|

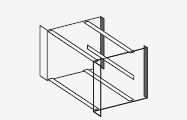

Filling flange

|

+Accessories : EMC (battery compatible) shielding shrapnel, vertical. |

|

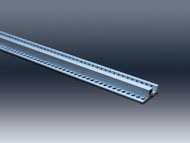

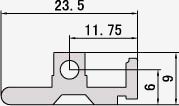

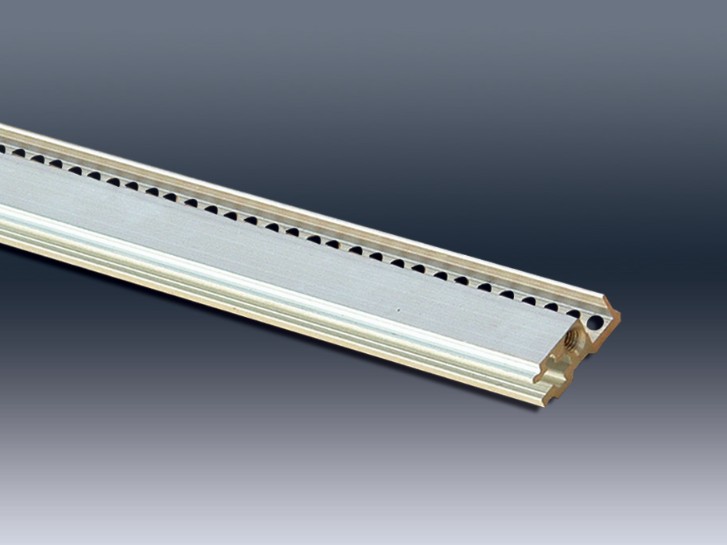

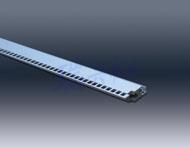

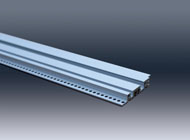

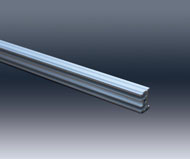

Horizontal beam |

|

|

Front horizontal beams Surface treatment: chromium acid passivation, anodic oxidation

|

Anodic oxidation, chromium acid passivation

+ Accessories :

One thread plate

M4X12 screw. 【Please see fasteners】 |

|

|

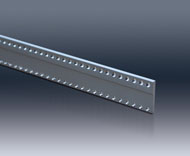

Rear horizontal beams Surface treatment: chromium acid passivation, anodic oxidation

|

Anodic oxidation, chromium acid passivation

!In addition to: M4X12 screw 【Please see fasteners】 |

|

|

Rear horizontal H beams

|

Anodic oxidation, chromium acid passivation

+Accessories : one thread plate

M4X12 screw 【Please see fasteners】 |

|

|

Front horizontal extension beam Surface treatment: chromium acid passivation, anodic oxidation

|

Anodic oxidation, chromium acid passivation

+Accessories : One thread plate

!In addition to: M4X12 screw 【Please see fasteners】 |

|

|

Strengthen the front beam

|

Anodic oxidation, chromium acid passivation

One thread plate ! In addition to: M4X12 screw 【Please see fasteners】 |

|

|

Rear level T Angle beam

|

Includes 2 M4X12 fixed screw

! In addition to: M4X12 screw 【Please see fasteners】 |

|

|

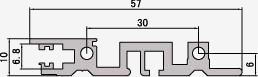

Rear horizontal middle beam

|

Chromium passivation acid

! In addition to: M4X12 screw 【Please see fasteners】 |

|

|

Rear horizontal new middle beam

|

Anodic oxidation, chromium acid passivation

+ Accessories : Two threaded plate !In addition to: M4X12 screw 【Please see fasteners】 |

|

|

Z beam Surface treatment: chromium acid passivation, anodic oxidation

|

|

|

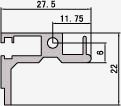

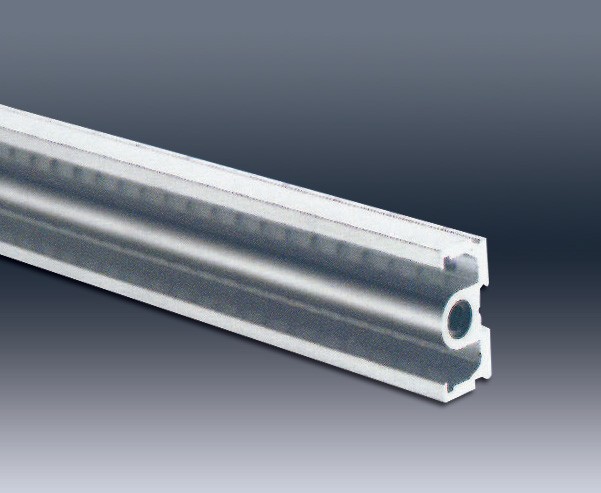

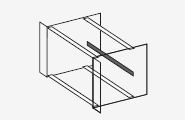

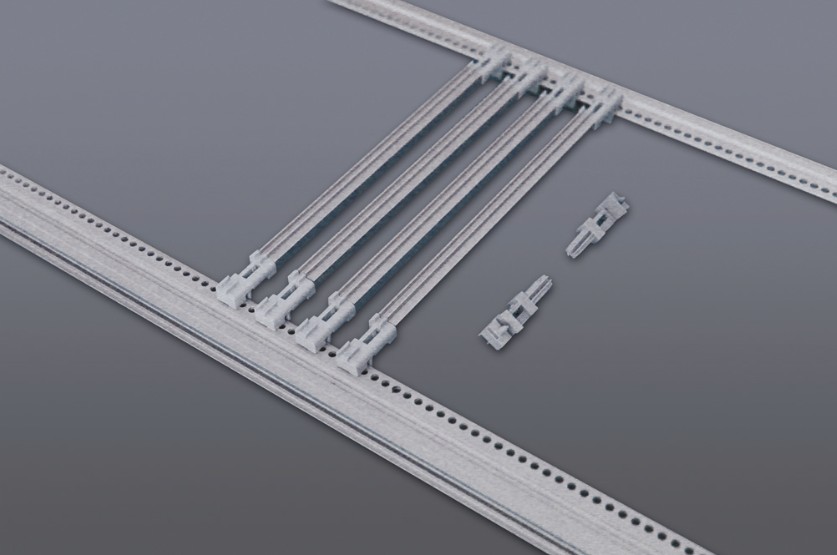

Guide |

|

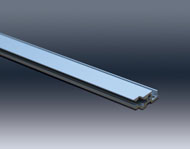

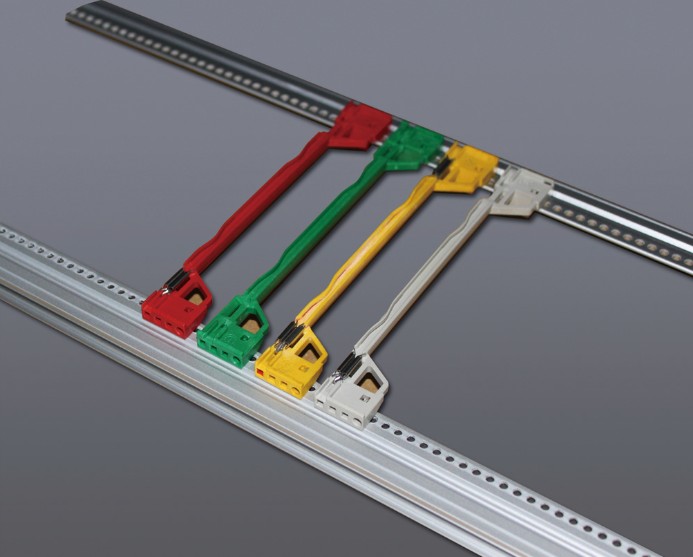

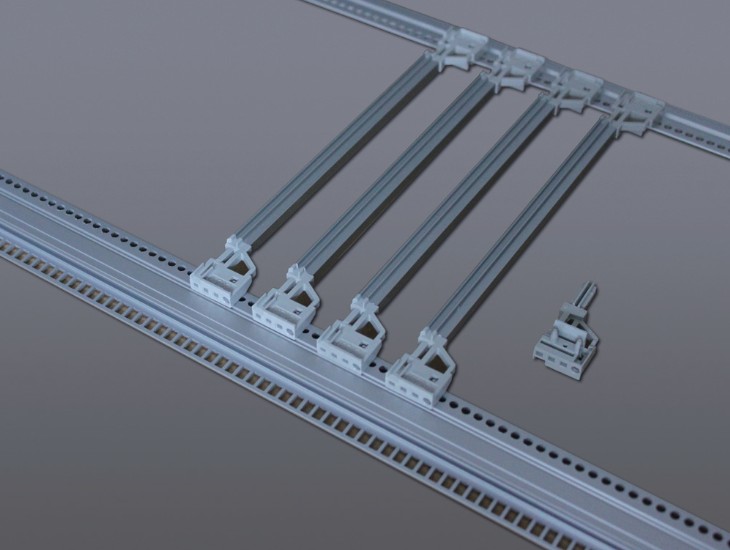

The plug-in board guide plastic (RX-B) |

+Accessories: Contact spring |

|

The plug-in board |

+ Accessories: Contact spring |

|

Coded plug-in guide plastic |

Note: only be used together with type V plug/pull booster + Accessories: 1), coding pin |

| RXB | ¥ | ||||

| 红色 | 绿色 | 黄色 | 灰白色 | ||

| 160 | |||||

| 220 | |||||

|

Coded plug-in guide combination |

+ Accessories: 1), coding pin |

|

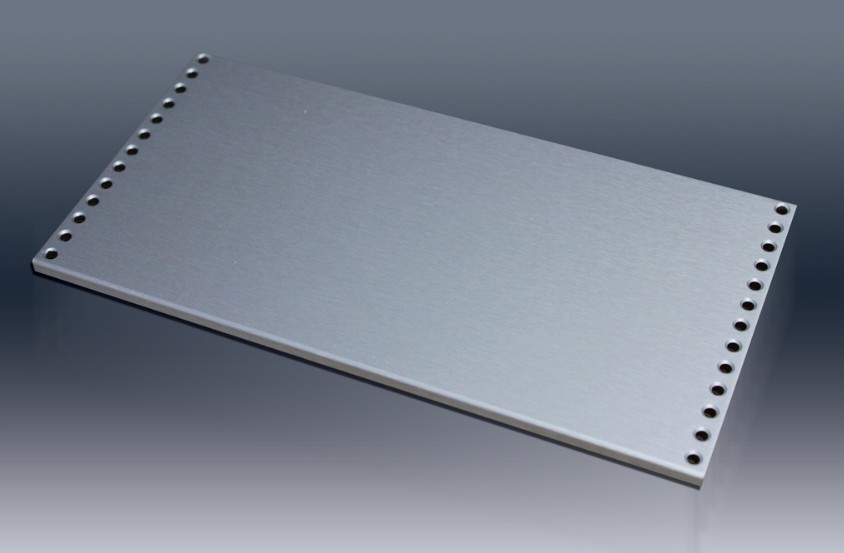

Cover plate |

|

Ventilation cover plate

Cover fittings |

|

|||||||||||||||||||||||||||||

|

Block cover plate

+ Accessories: |

|

|||||||||||||||||||||||||||||

|

Side panel |

|

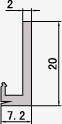

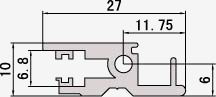

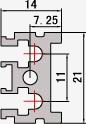

RX-B type |

|

| T(mm) |

t(mm) |

2U | 3U | 4U | 5U |

6U |

| |

|

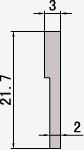

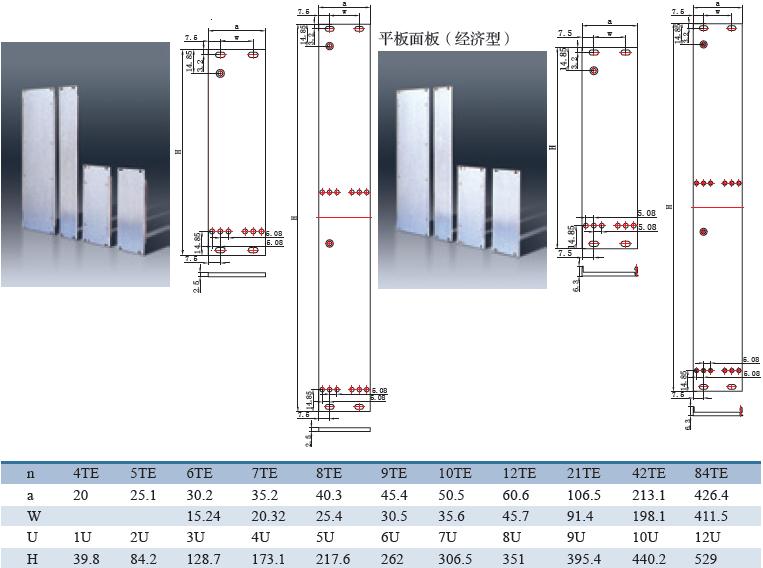

Panel 【更多】

|

| Material: aluminium magnesium alloy 6063 A-T5

Height: 1 U, 2 U, 3 U, 4 U, 5 U, 6 U, 7 U, 8 U, 9 U, 10 U Width: 4 TE, 6 TE, 8 TE, 10, 12 TE, 14 TE, 20 TE, 21 TE, 40 TE, 42 TE, 84 TE Features: the use of aluminium magnesium alloy profile production, can install electromagnetic shielding shell fragments, Surface treatment: chromium acid passivation/anodic oxidation/coating/spray paint Color: aluminum instinctive quality/black/other

* process in accordance with customer’s requirements

|

| |

|

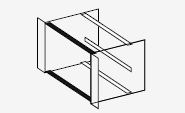

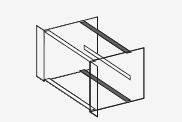

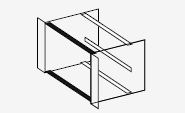

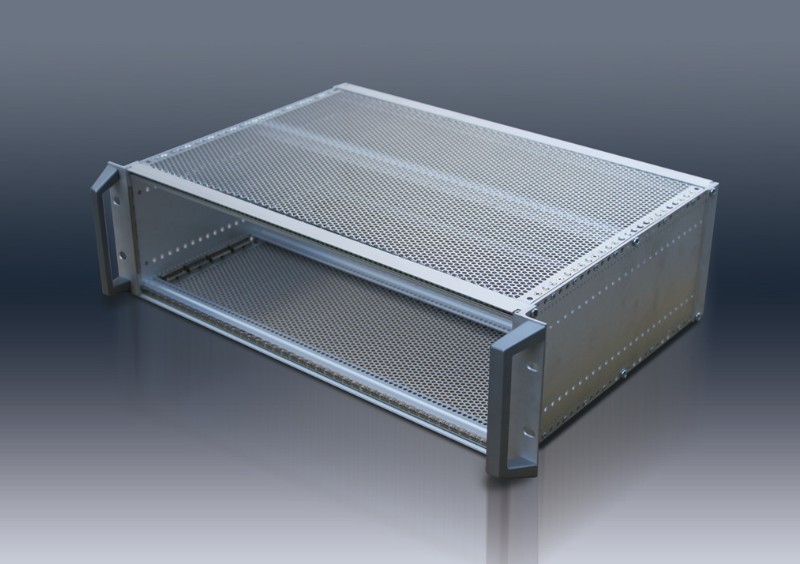

Plug-in box 【更多】

|

|

Plug-in box

component put- in box, divided into type A and B type

|